RSM-1 TECHNICAL HIGHLIGHTS

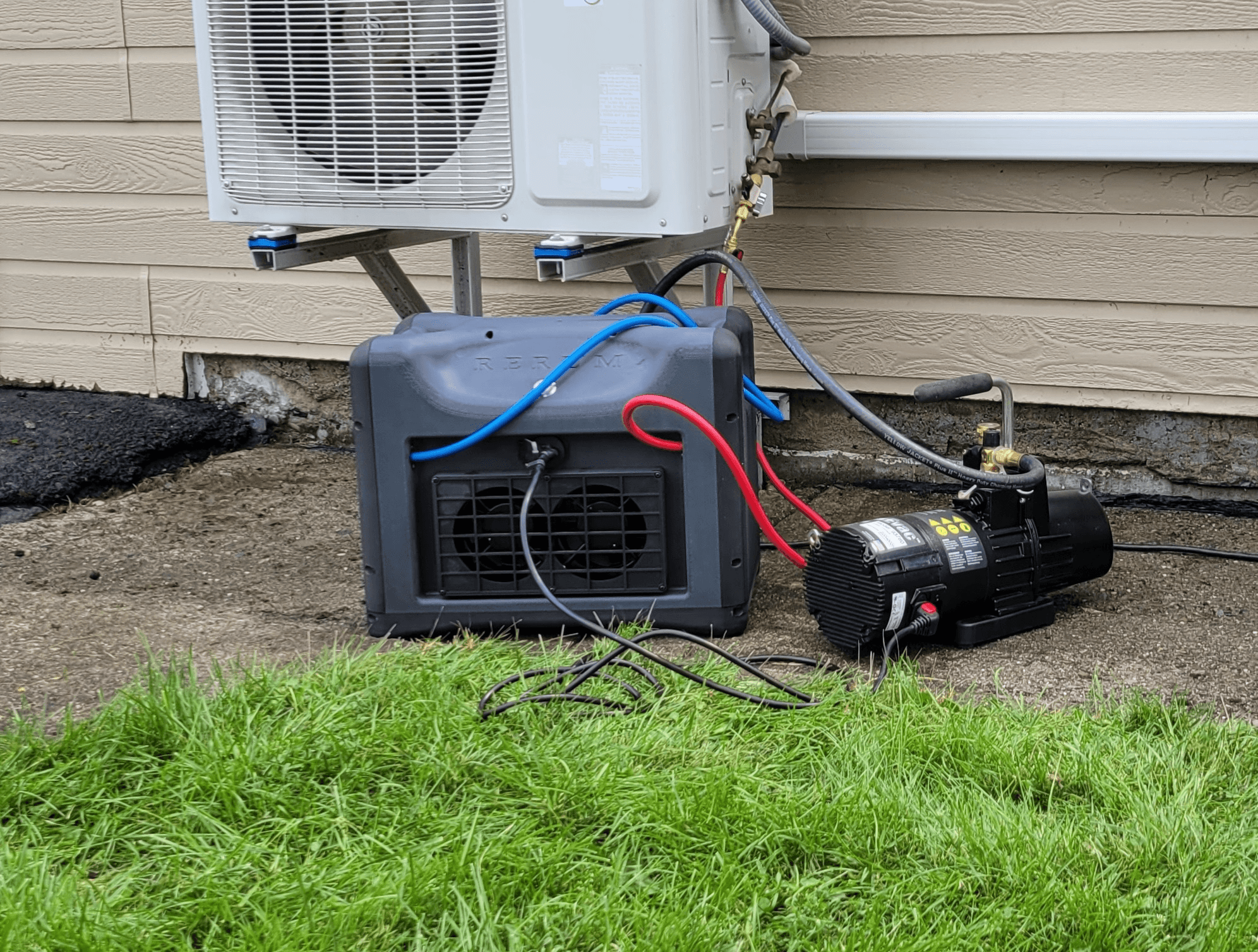

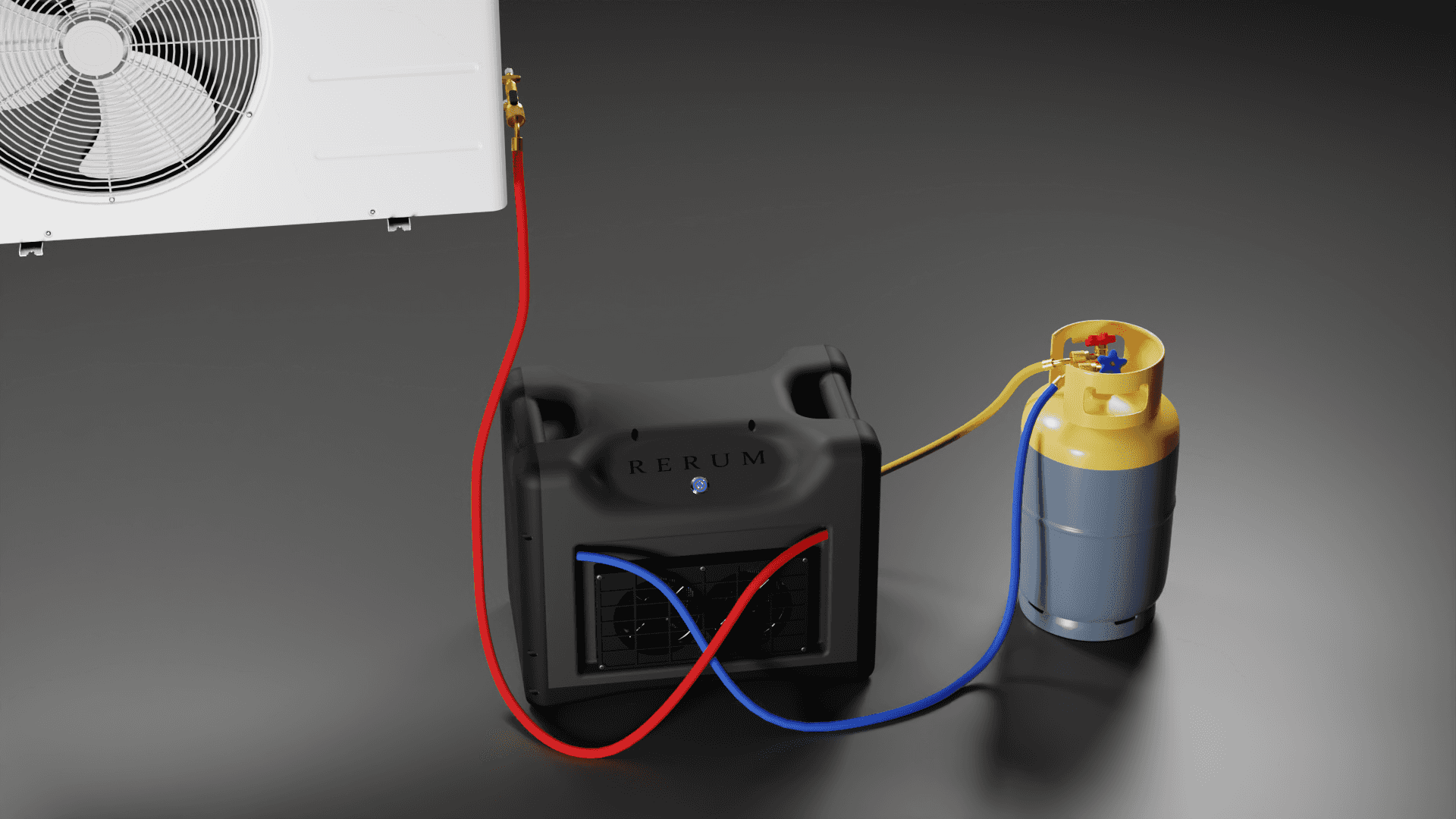

Fully Automatic Recover/Recycle/Recharge

From a simple press of a button, the RMS-1 goes over the recover, recycle, evaluate and recharge process of the equipment to bring it back to its factory specifications.

Automatic Oil Drain

The RMS-1 features an automatic oil separation cycle that can be activated or desactivated. The collected oil drain's into the used oil bottle, located on the side of the machine.

Automatic Air Purging

The RMS-1 is designed to automatically purge non-condensable gases such as air present in the storage tank. When the pressure and temperature exceeds the algorythm value, the machine automatically purge the non-condensable gases.

Vacuum Process

Connecting a standard vacuum pump to the RMS-1 designated port and receptacle allows the RMS-1 to manage the vacuum operation effectively. The built-in micron gauge simplifies the vacuum process by providing real-time monitoring and ensuring that the vacuum level meets the required standards.

Low Temperature Active Recharge

The RMS-1 take advantage of its compressor pressure differential to facilitate the recharging process during low ambient temperature. Thus eliminating the need to run the equipment during the refrigerant recharge.

Flush Mode to Avoid Contamination

The Flush Mode feature is used to remove any residual oil and contaminants from the unit and hoses. Thus reducing the risk from cross contamination.

Filter Life and Refrigerant Usage Monitoring

The RMS-1 has a unique filter system that ensures the refrigerant recovered and recharged is clean and moisture-free. Its filter life is monitored to ensure the system is working correctly. A maintenance reminder prompts when it's ready to change the filter.

Cloud Reporting

From the integrated firmware, data can be transferred to the cloud server throught the connected smart device. Additional information of servicing equipment, such as GPS coordinates and refrigerant metrics, can be accessed from this data at any point in time. Regulatory and custom reports can be generated automatically.

Bluetooth Smart Device App Interface

Control and operate the device from the comfort of your smart device. Receive notifications and monitor ongoing progress

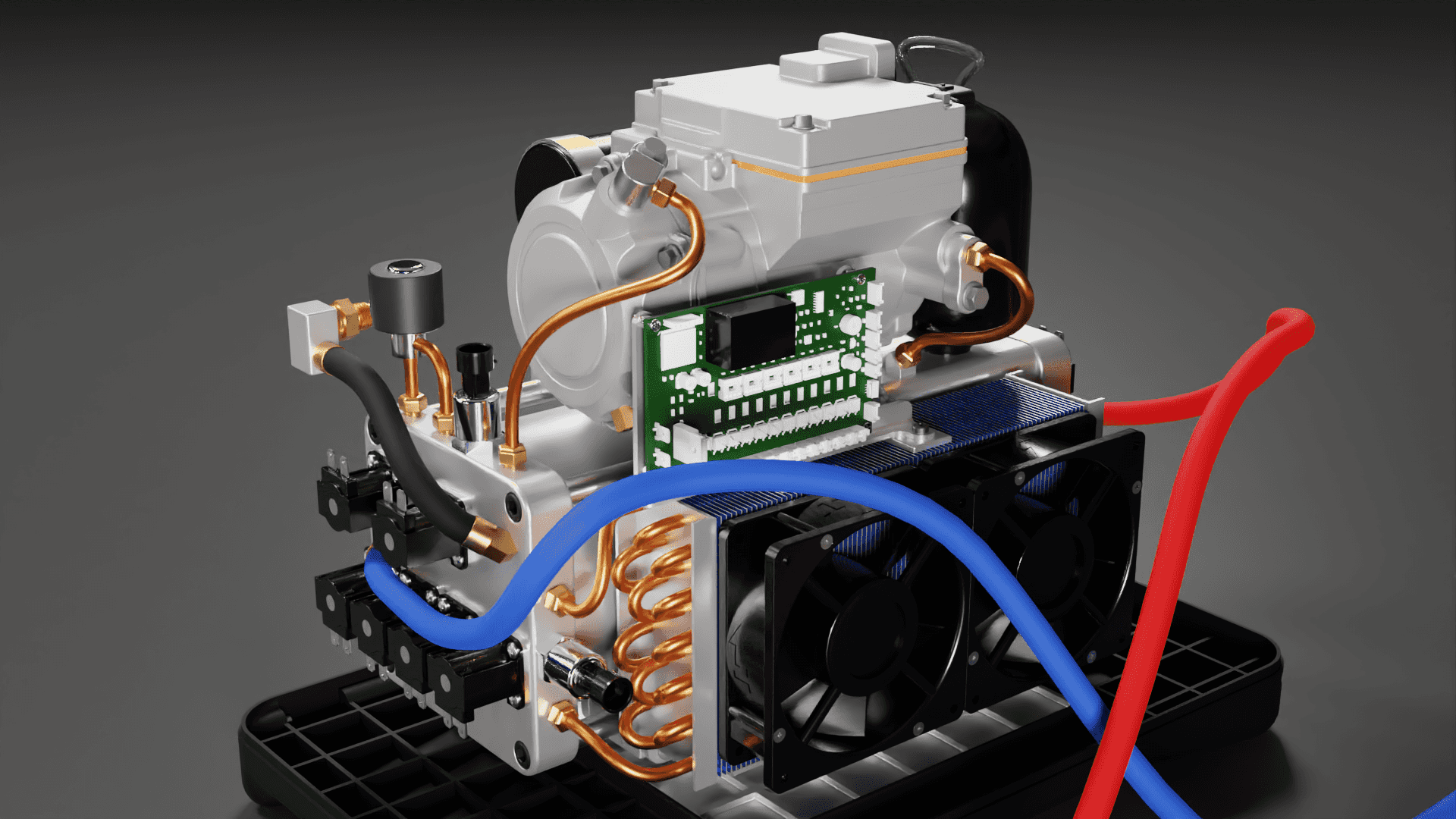

Variable Speed Inverter Compressor

Fitted with an intelligent drive system, the variable speed compressor continuously changes speed to match demand. Quieter in operation, it also reduces the compressor running in an unloaded state, thus increasing the system’s longevity

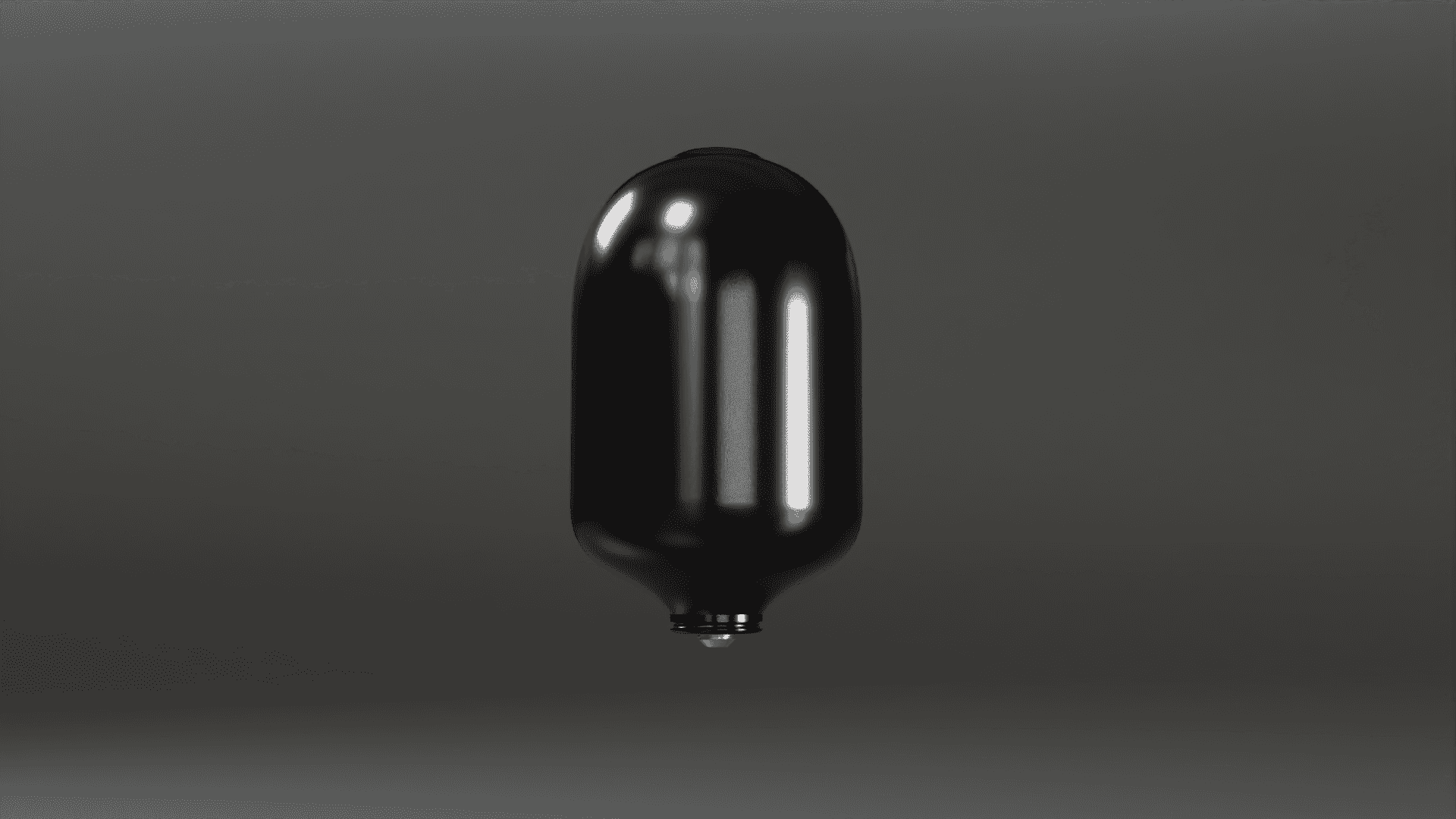

Optional External Tank Expandability

With the ability to add an external recovery tank to the RMS-1, the maximum recovered refrigerant can be increased up to 25 pounds.

Replaceable Filter Drier

To ensure the refrigerant system stays clean and dry, the Rerum recovery management system uses a proprietary filter drier developed explicitly for the RMS-1.

Over-the-Air Software Updates

Software updates are an integral part of the overall user experience as they will contain important feature enhancements. Via a simple wifi connection, the RMS-1 has the capability to stay current with the latest features.

Technical Specifications

- ● Refrigerant Type: R410A

- ● Recovery Rate: up to 1 lbs/min

- ● Load Cell Precision: +/- 0.5 Oz

- ● Internal Tank Capacity: 7lbs @ R410A (4L)

- ● Operating Range: -4°F to 104°F (-20°C to 40°C)

- ● Power Source: 120 VAC - 60 HZ - 10 Amp

- ● Dimension W x D x H: 19.25" x 12.25" x 16" (48.9cm x 31.1cm x 40.6cm)

- ● Dry Weight: 55lbs

- ● Warranty: 1 Years